CONCRETE MIXERS

We can find you a mixer solution to install in a new or existing concrete batching plant.

Concrete mixers are long lasting, robust and user friendly. Mixer options available:

- Tecwill countercurrent planetary mixers from 0.25 to 3.0 m³

- BHS twin-shaft mixers from 1.0 to 4.5 m³

Both mixers are available with a wide range of options.

The mixer is designed to allow short mixing times, even for hard-to-mix zero slump concrete through the use of the outstanding counterflow mixing principle. More than 60 years of experience gives proof of the mixer’s reliability, effectiveness and efficiency in numerous demanding applications.

- Short mixing time

- More concrete per hour, maximum production

- More profit during the mixer’s lifetime

- Simple and durable design, less downtime

Twin-shaft mixing technology is suitable for all formulas and offers a wide range of benefits. The mixing procedure has a significant effect on the mixture quality produced and the economic efficiency of the production process.

- Consistently high mixture homogeneity and short mixing cycles

- Optimum energy efficiency

- Design results in low wear and robustness

- Easy to maintain

- Efficient concrete production

- Fast discharge, wide bottom hatch

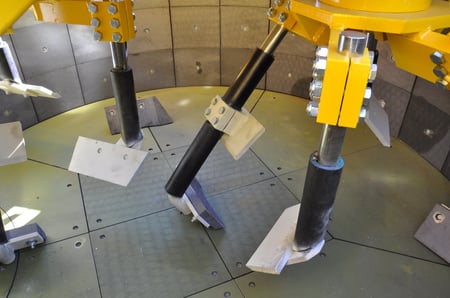

What does a planetary mixer consist of?

Using the outstanding counterflow mixing principle, mixing is perfect – even after a few full turns. The mixing shovels rotate in a slightly offset manner with every revolution, ensuring no dead spots.

The planetary mixer is suitable for:

- Precast concrete

- Zero slump concrete for hollow-core slabs and paving stones

- Ready-mix concrete

- Shotcrete with fibers

- Self-consolidating concrete

- High-strength concrete up to 150 MPa

- Mixing new cementitious materials and activators like slag, fly ash and geopolymer cement

The mixer is always equipped according to customer needs. Below are some of the basic mixer equipment options available:

- Mixer frame and discharge hatch

- Standard wear plates

- Inlets for scales

- Concrete temperature sensor

Typical mixer options:

- Special wear plates

- High-pressure washing system

- Sample hatch

- Camera hatch with LED light

- Variable-speed drive to control the mixer rotation speed

- Mixer control panel

To get batch water to the mixer quickly and stably, using pump discharge is recommended. Water is pumped from the water scale through nozzles into the mixer.

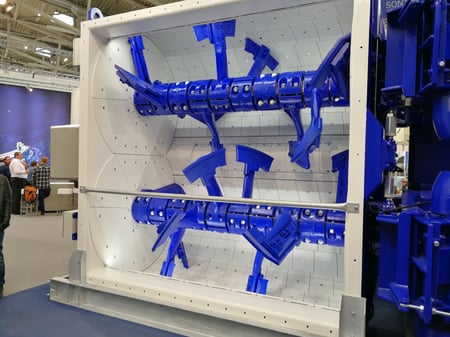

What does a twin-shaft mixer consist of?

Twin-shaft mixing technology is especially suitable for ready-mix concrete. It’s a good option also for mixing:

- Roller-compacted concrete (RCC)

- Paving concrete

- Lean concrete

- Backfill

The mixer is always equipped according to customer needs. Below are some of the basic twin-shaft equipment options available:

- Mixer frame and wide discharge hatch

- Wear plates

- Inlets for scales

- Concrete temperature sensor

- Centralized lubrication system

Typical equipment options:

- Special wear plates

- High-pressure washing system

- Sample hatch

- Camera hatch with LED light

- Variable-speed drive to control the mixer rotation speed

- Mixer control panel

Mixer-scale package

When retrofitting a mixer, other process-related equipment may also need to be replaced. In addition to complete concrete plants, Tecwill manufactures equipment to retrofit existing concrete plants. A suitable package can be designed and manufactured according to your project specifications.

Tecwill’s delivery and service package can include the following:

- Design of new equipment

- Mixer

- Cement scale

- Water scale

- Additive scale

- Aggregate scale

- Electric system upgrade

- Batch control system upgrade

Frequently asked questions

These are questions we’re often asked. We hope you find these helpful. If you still have a question we haven’t addressed, please contact us directly.

The best mixer depends on the size of the concrete plant. For a small plant, a planetary mixer can be used for batch sizes up to 2.5 m3.

For larger concrete plants, the twin-shaft mixer is more practical. A large planetary mixer would take up too much space and time to empty. A twin-shaft mixer discharges concrete faster and is the right choice when the mixer batch size size is at least 3.0 m3 or larger.

Self-consolidating concrete is an extremely liquid mixture, which flows easily and consolidates with its own weight using an efficient retarder as an additive.

Tecwill’s artificial intelligence controls the dosage and weighing for accurate material amounts in each dose. Mixing is performed as a so-called wet mixing method in a planetary mixer, which shortens the mixing time and improves capacity.