Why Tecwill?

Tecwill Ltd. is a world leader in producing high-quality mobile and stationary concrete batching and mixing plants and control systems, offering its customers reliable and modern solutions for the production of high-quality concrete.

Extensive practical experience

Since starting in 1994, Tecwill has become a world leader in the design and

fabrication of high-quality modular concrete batch plants with innovations to reduce carbon footprint and production costs of concrete production.

Headquartered in Joensuu, Finland, and operating in Europe, North America, Asia and Africa, we have commissioned over 300 plants within the ready-mix, precast, block and paving stone, mining and construction segments.

Our modular, high-performance plants can be set up quickly and relocated while maintaining some of the tightest tolerances in the industry. All our plants are pre-wired and tested before shipment.

Tecwill’s operations are based on extensive experience in the field of manufacturing concrete mixing plants and continuous product development.

Some examples of this include:

- Arcamix concrete plant concept with higher capacity and efficiency

- Self-learning AI-based dosing and weighing algorithm that simply makes the world’s best concrete

- OptiMoist aggregate moisture measuring system that measures all aggregate fractions with one sensor

- “Flying” aggregate weighing system that saves raw materials and reduces CO2 emissions from concrete production

Why choose Tecwill – how are we different?

Tecwill’s high-precision “flying” weighing system saves up to 30 kg/m3

(50 lb/yd3) in cement and reduces CO2 emissions in concrete production.

Our “flying” aggregate weighing system eliminates the need to add extra cement to the mix design to compensate for inaccurate weighing and dosing.

- More accurate weighing

- Less cement

- Correct slump

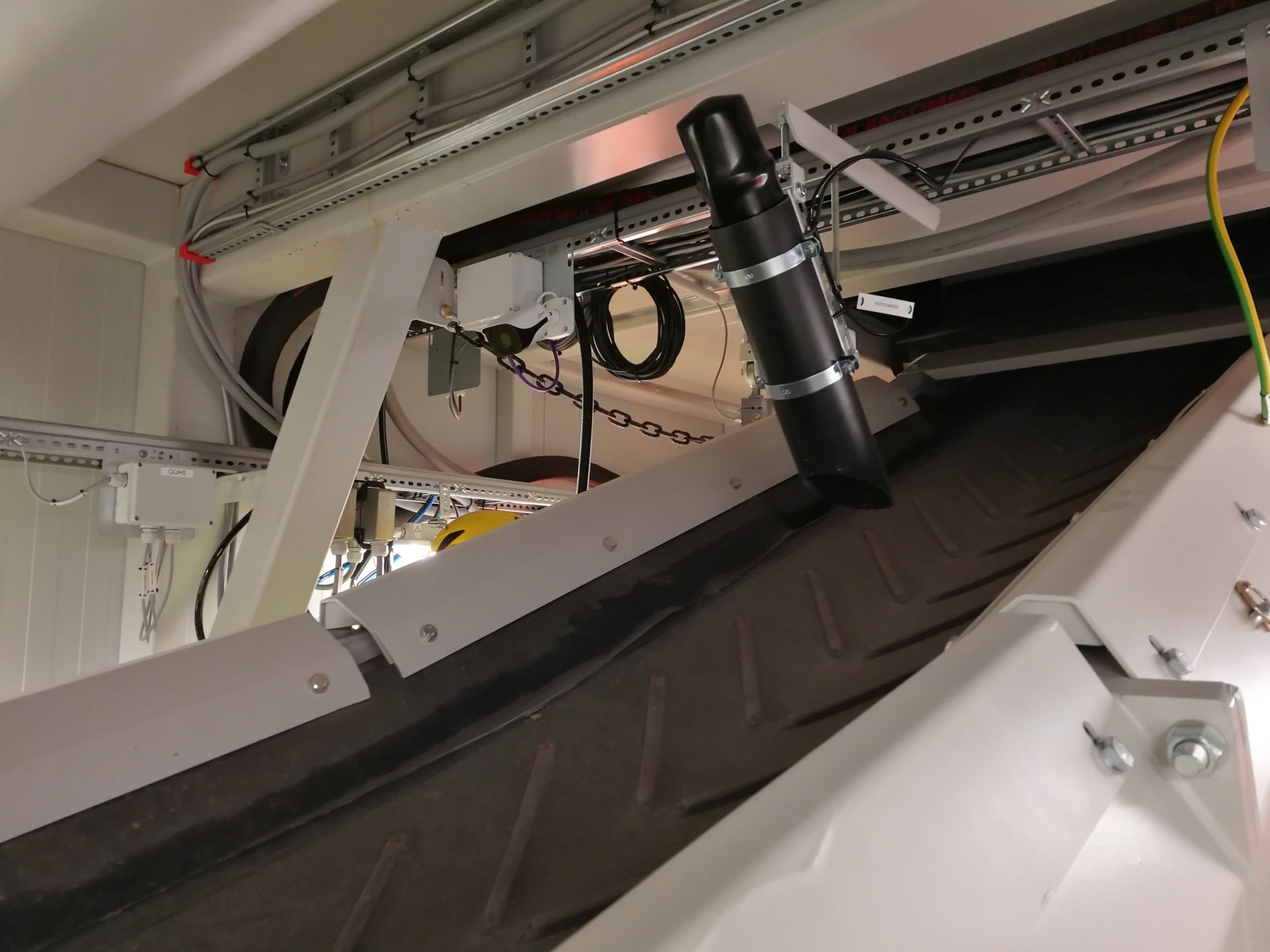

Tecwill’s OptiMoist system allows moisture content

of all aggregate fractions to be measured

by one common moisture probe.

The right amount of water in the concrete batch shortens the mixing time and reduces quality issues.

- Improved aggregate moisture control

- Correct slump

- Lower probe costs

- Easy calibration

Batch control system with a self-learning artificial intelligence-based

algorithm to control the dosing and weighing of materials.

Self-learning dosing and weighing adjusts the process in real time based on the production parameters. Benefits include:

- High-accuracy material weighing

- The right amount of raw materials in each batch

- Less cement

- Reduced CO2

- Shorter mixing time

Tecwill’s history

- 1994 – Viljo Ryhänen founded the company

- 1997 – First export delivery to Norway

- 2001 – Participated for the first time at the international BAUMA construction machinery exhibition in Munich

- 2004 – Established the first Tecwill subsidiary in Poland – Tecwill Polska

- 2008 – New office and production facilities were completed in Joensuu, Finland – a significant milestone in the assembly of concrete plants

- 2012 – Timo Ryhänen became CEO

- 2013 – The Arcamix concrete plant was launched

- 2015 – The LEAN philosophy of thinking and leadership was introduced

- 2018 – A self-learning artificial intelligence-based algorithm for dosing and weighing control was developed

GLOBAL OPERATIONS

Tecwill’s diversified business operation model aims to make our customers’ investment as efficient and beneficial as possible.

“A concrete batch plant cannot afford downtime or off-spec quality. This means maintenance, service and spare parts services have an essential role alongside installation, training and expert support,” says Timo Ryhänen, President and CEO. He believes the best solutions are developed in cooperation with customers. This ensures that both the plant and the necessary services are delivered to best satisfy customer expectations.

Carbon reduction and environmental issues are also becoming increasingly more important in the concrete business. This emphasizes the role of strong expertise, new technology and innovative solutions.

Competition has intensified, with low-cost producers and other newcomers testing the market and compromising on quality. In addition, construction requirements, such as environmental and concrete standards, have become much more rigorous.

“We are meeting the industry challenges with continuous product development and the latest technology,” says Janne Tuomikko, VP Business Development & Sales at Tecwill.

“A concrete mixer alone is not enough to make a modern concrete plant. The whole process has to be controlled from start to finish. And the plant has to operate in widely varying conditions, for example, during the winter,” he continues.