OptiMoist – aggregate moisture measuring

Benefits of Tecwill OptiMoist aggregate moisture measuring system

Improved aggregate moisture measuring with more accurate material dosing and weighing leads to significant savings in concrete production.

The right amount of aggregates and water in each concrete batch shortens the mixing time

- Right amount of aggregates and water in each batch

- Shorter mixing time

- Less wear

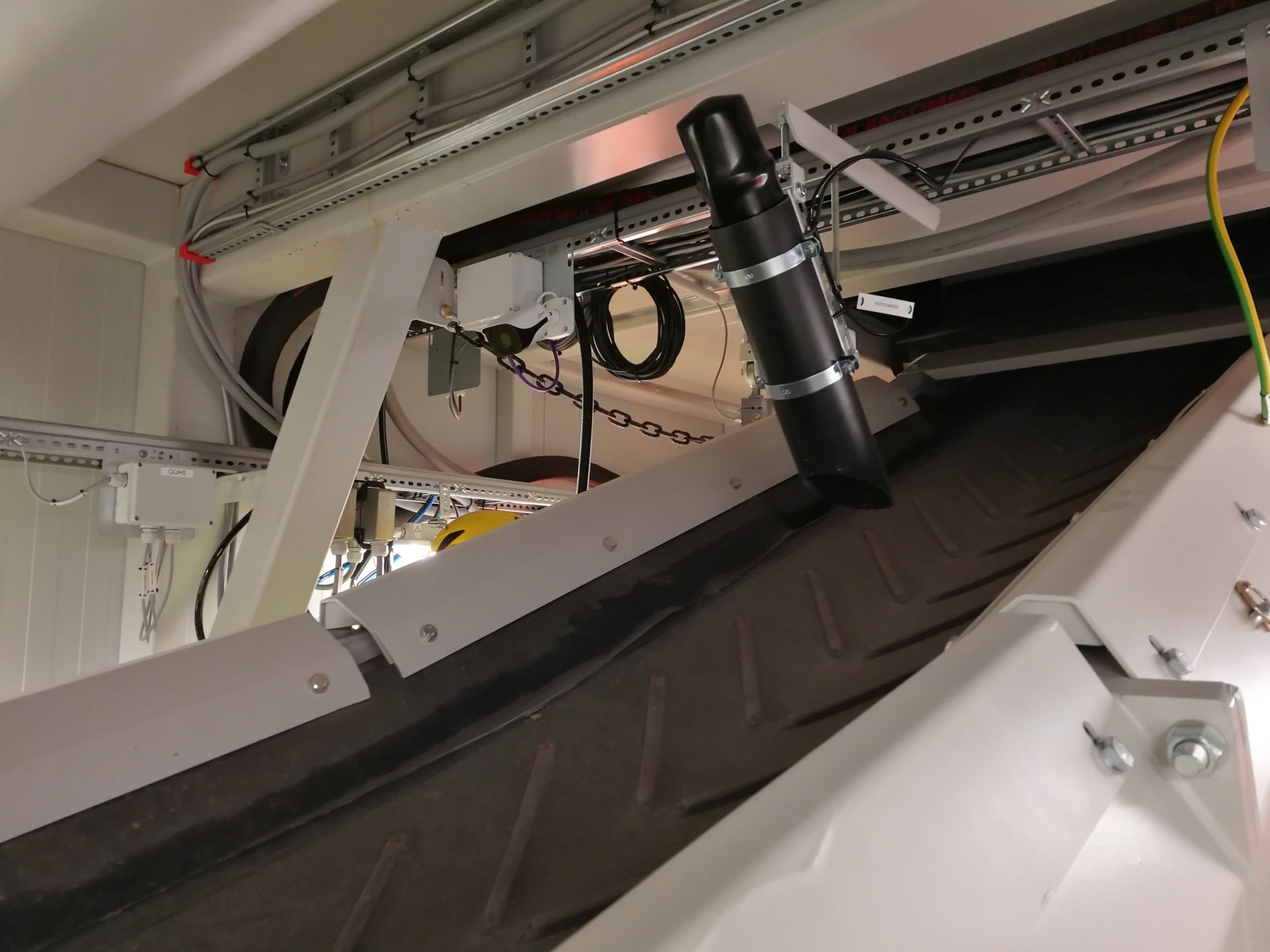

Tecwill's “flying” weighing system with OptiMoist allows the moisture content of all aggregate fractions to be measured by one common moisture probe.

The right amount of batch water reduces quality issues

- Improved aggregate moisture control

- Correct slump for wet and dry mixes

- Lower probe costs

Only one common aggregate moisture probe for all different aggregate

fractions. Easy probe calibration for different stones and sands.

One moisture probe for all fractions

- Lower probe costs

- Easy calibration

Tecwill moisture measuring for aggregates, concrete mixer and self-consolidating concrete

In concrete production, the aggregate moisture content is measured and the amount of water accompanying the aggregates is calculated. The modern batch control system automatically reduces the amount of water entrained in the aggregates from the batch water and corrects the aggregate amounts accordingly.

The moisture content of zero slump concrete can be measured in a mixer with a probe. The mixer probe informs the batch control system about the moisture content, and the batch control system adjusts the slump according to parameters.

Self-consolidating concrete (SCC) normally uses a dry-mix procedure. With Tecwill’s improved aggregate moisture control and mixer moisture control, SCC can also use a wet-mix procedure.

Tecwill’s “flying” aggregate weighing and dosing system, together with OptiMoist moisture measuring system, allows the moisture content of all aggregate fractions to be measured by one common moisture probe.

This probe can be an optical non-contacting probe or microwave skid-probe. The probe measures the moisture content of each fraction one by one and transfers moisture data to the batch control system.

The batch control system can easily calibrate the probe for different stones and sands.

To ensure the moisture content of zero slump or low slump concrete, a special moisture probe can be installed in the mixer. Based on the probe data, water can be added to the concrete mixer, and the moisture content can be adjusted as desired.

Zero slump concrete is used in hollow-core slabs, paving stones, concrete blocks and masonry products.

Exact moisture content is important. Even a small mistake in the water amount can create quality issues and tone variations.

Self-consolidating concrete (SCC) normally uses a dry-mix procedure. With Tecwill’s improved aggregate moisture control and mixer moisture control, SCC can also use a wet-mix procedure.

Self-consolidating concrete or self-compacting concrete is a highly “liquid” mix that flows easily and compacts under its own weight. A high-range superplasticizer with a water-reducing admixture is used in the mix.

The traditional mixing method is to first mix the dry ingredients – cement and aggregate – and then adjust the batch moisture. Next, water and a superplasticizer are added. This method’s mixing time is very long, reducing plant capacity and increasing mixer wear.

Tecwill’s wet method improves moisture control. The artificial intelligence-controlled dosing and weighing system ensures accurate material amounts for each concrete batch. The mixing uses the so-called “wet mixing” method, which shortens mixing time and improves capacity.

READ MORE ABOUT OUR AGGREGATE MOISTURE PROBES

Aggregate moisture must be measured nearly in real time, so that variations can be taken into account when weighing the raw materials in the concrete batch. The moisture content and water amount in the aggregates affect the concrete batch in the following ways:

- The water amount to be weighed on the water scale

- The aggregate amount, taking into account the amount of water included

- The incoming water-cement ratio and concrete quality

Read our blog on how to measure aggregate moisture at a concrete batch plant.