The impact of the COVID-19 pandemic increases new challenges and raises questions. What kind of impact this crisis brings to the concrete plant deliveries and installation? Is it possible to install and start-up the concrete plant during this crisis, stay on the schedule and still pay attention to safety of the employees? Now we will compare different type of concrete plants and their suitability for this exceptional period.

Things which should be considered in installation during the exceptional period

The most relevant thing that effects to the installation time is the readiness of the concrete plant at the manufacturing factory. The readiness of the plant is determined by its type. Concrete plant can be so called “kit delivered in parts and assembled at the site”. Kit includes equipment, support construction, bolts, and nuts, which are assembled at site by the buyer. In addition, electricity, water pipes and insulation, will require installation among other things. A project like this takes a lot time and needs plenty of manpower and crane hours. During this crisis, when safety is the most important, this clearly is not the best option.

Water pipelines, electricity and thermal insulation

If the plant is going to be used also in wintertime, its needed insulated plant. Concrete production needs also water and electricity. Are these equipment, pipelines, and cables pre-installed or needed to be install at the site? How about insulation panels or even the frame for these? If the concrete plant is designed for winter use, are these parts essential. It is clear that, the concrete plant with as many pre-installed equipment as possible, is a better option during the exceptional period. This makes the installation time shorter, the need of employees smaller and hence, reduce the risk of infection.

Let us now compare different types of the concrete plant and their pros and cons:

CONCRETE PLANT KIT |

CONCRETE PLANT WITH MODULES(PRE-INSTALLED SUMMER MODEL) |

CONCRETE PLANT WITH MODULES(PRE-INSTALLED WINTER MODEL) |

|

PROCESS EQUIPMENT |

-Not installed, installation will be done at the construction site |

+/- Partly installed |

+ Pre-installed at the factory |

SUPPORT CONSTRUCTION |

-Not installed, installation will be done at the construction site |

+/- Partly installed (frame for the insulation panels missing) |

+ Pre-installed at the factory |

ELECTRICITY |

-Not installed, installation will be done at the construction site |

+/- Partly installed (property electricity is often missing) |

+ Pre-installed at the factory |

WATER PIPES |

-Not installed, installation will be done at the construction site |

-Not installed, installation will be done at the construction site |

+ Pre-installed at the factory |

THERMAL INSULATIONS |

-Not installed, installation will be done at the construction site |

-Not installed, installation will be done at the construction site |

+ Pre-installed at the factory |

INSTALLATION TIME AND THE NEED OF EMPLOYEES |

- Long installation time (even for months) - The need for manpower is huge - Its needed specialists from supplier at the site |

- Quite long installation time - The need for manpower is big - Its needed specialists from supplier at the site |

+Fast installation time + The need for manpower is small +No necessary needed specialist from supplier at the site, can be done remotely

|

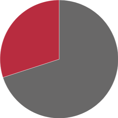

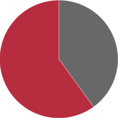

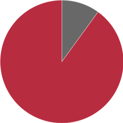

THE PROCENTAGE OF PLANT PURCHASE PRICE OF TOTAL COSTS (EQUIPMENT AND MANPOWER) |

30% |

60% |

90% |

Resume

As you can see from the table above, the best option during the crisis is pre-installed winter model. It is safe, because the number of staff required is small and the installation can be completed in a really short time - even in a week. Once the concrete plant has been tested before delivery, its functionality can be ensured and thus the installation time and startup of the plant can be speeded up.

In addition to this, winter model can be installed by the site’s own staff and therefore there are not necessarily needed specialist from supplier. However, if the need on specialist’s help arises, it can be easily done remotely. This minimizes the risk of the infection.

Tecwill pre-installed concrete plants

Tecwill delivers fully pre-installed and tested winter concrete plants. All the necessary modules and equipment of the plant, such as electricity, water pipes and insulation, are installed and the plant is tested before delivery to the customer. This kind of concrete plant can be installed and started- up easily during Corona time. If necessary, Tecwill also offers remote support, for example with a video connection, which is perfect for exceptional times.