In June 2019 Tecwill Oy delivered Cobra C120 mobile concrete batching plant to Northern Sweden for a wind turbine projects. The first part of project includes 179 windmills, second one 440 windmills. The total project scope is estimated to be more than 1100 windmills, so it will be one of the biggest windmill parks in the World.

The Cobra plant was installed on steel beam foundations, Tecwill delivery included also mobile loading ramp elements for aggregate bins. This is easy and fast way to make foundations for the plant.

Before the concrete batching plant was packed and delivered to Sweden, it was pre-installed and tested in Finland. The testing was done both mechanically and electronically. Careful preparation enabled the fast start up at the site. This also enabled the start of the production without any delays.

To get the plant in operation there is needed electricity and water connections. For electric supply, customer used two generators to act as a power source. In this project the water was pumped from the drilled well directly to Cobra plant’s buffer tank.

Cobra C120 is a mobile concrete batching plant so it’s possible to move if its needed. Unloading, transferring and installation is fast and easy with this plant.

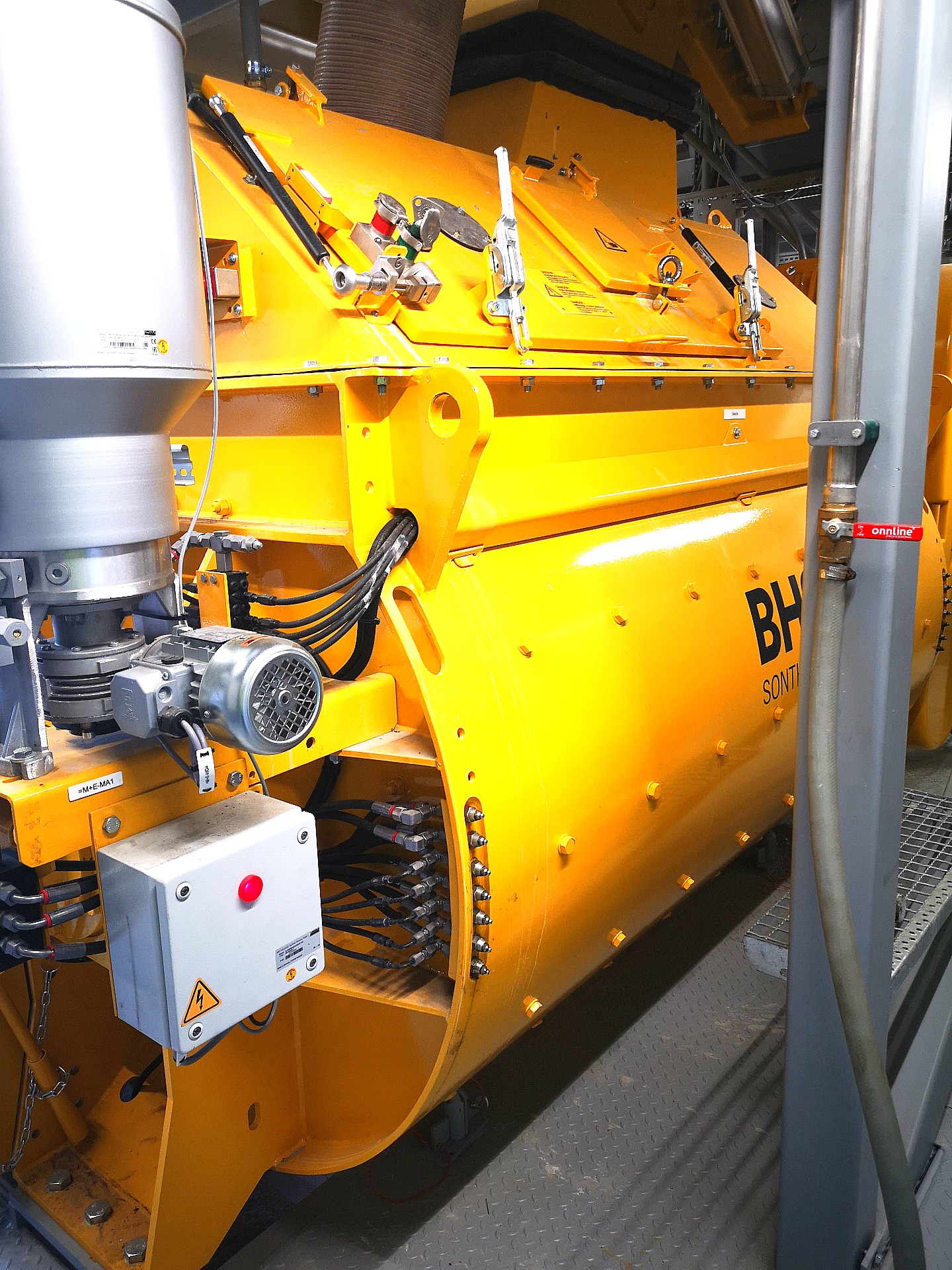

The mixer at the Cobra C120 plant, is a twin-shaft mixer, which is perfectly suitable to mix fiber concrete. Additionally, a wide range of optional equipment is available for this plant. Special models can be designed according to the customer’s requirements. In this project there were also added a few of these equipment’s.

Aggregate moisture measuring of all fractions is precisely measured by an OPTICAL “non contacting” sensor. There is one common sensor for measuring all different aggregate fractions. Moisture data are passed on to the control system and are used for the calculation of the required amount of water to be dosed into the water scale.

With the "flying" aggregate dosing and weighing system is achieved very accurate dosing.

One important element of high-quality concrete production with Cobra C120 is a WillControl control system.The WillControl system supports the control of the concrete production starting from the mix design and ending to the quality control. Tecwill aggregate and water heating system with automatic mixing of temperature controlled concrete guarantees successful operation under the most challenging conditions.

Fiber dosing system is fully automatic. While the aggregate is moving in the weighing belt are the fibers dosed at the same time with the aggregate stream. That enables fibers to blend smoothly with aggregates and the result is a homogeneous fiber-aggregate mix. When using the “flying” weighing, can be avoided fiber clumps.

In addition to these for example, a camera surveillance system and a mixer camera were added to plant.

In this project, the customer wanted to ensure stable and high-quality production of ready-mixed and fiber concrete throughout the year. With the Cobra C120 they get easy to maintain concrete plant. Any future expansions in control, electrical systems or mechanics, for example, are now easy to implement. Also, the features in Cobra mobile concrete batching plant, makes future relocation of the plant easy.

If you have any further questions please feel free to reach out.